Cost factors

The two biggest factors behind the cost of a 3D printed part are the size and risk invovled. Parts with more complicated details and geometries are more prone to print incorrectly and fail the quality requirements and we therefore need to account for more attempts when making the price estimate. Bigger parts require more filament, increasing the cost of each attempt.

Here are some simple tips that can greatly affect the price of an order.

Quality

What we do

During our manual review of the price estiamte, we consider which settings are ideal based on the 3D-model and your notes to us.

For example, parts intended for decoration or prototyping usually don't need to be as durable andcan be made with less material inside (infill)

Please note that the automatic price estimate can't account for the intended use case of a model.

What you can do

Design your model with fewer small and complicated details if they aren't necessary.

Let us know what the part will be used for (in the order notes or by email). We can take that into account by adjusting the settings on our side or suggesting changes to your design.

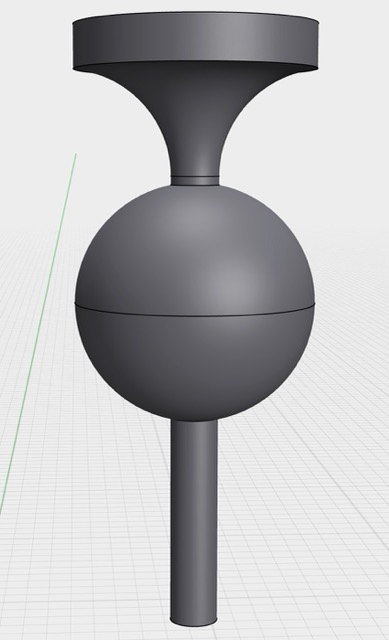

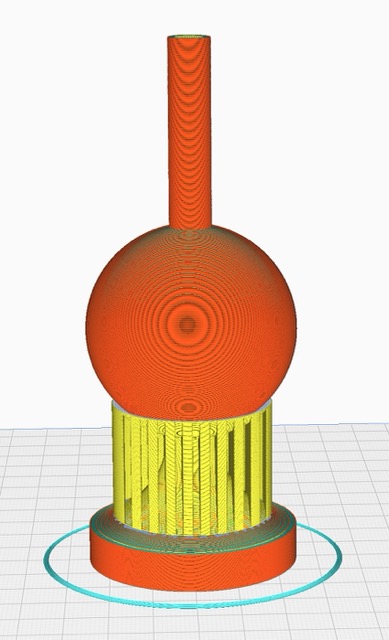

Supports

Supports are structures that are printed below the actual model. These are used to support parts of the model that would otherwise be printed in thin air.

What we do

We will generally orient the model such that the least supports are used. However, in cases where durability or quality are a priority, it could be benefitial to print in an orientation that requires more supports .

What you can do

You redesign your model such that fewer support structures are required. Try separating complex parts into several pieces that fit together.

The price calculator does not take support structures into account. If you would like immediate feedback on your design, consider exporting it in a different orientation.

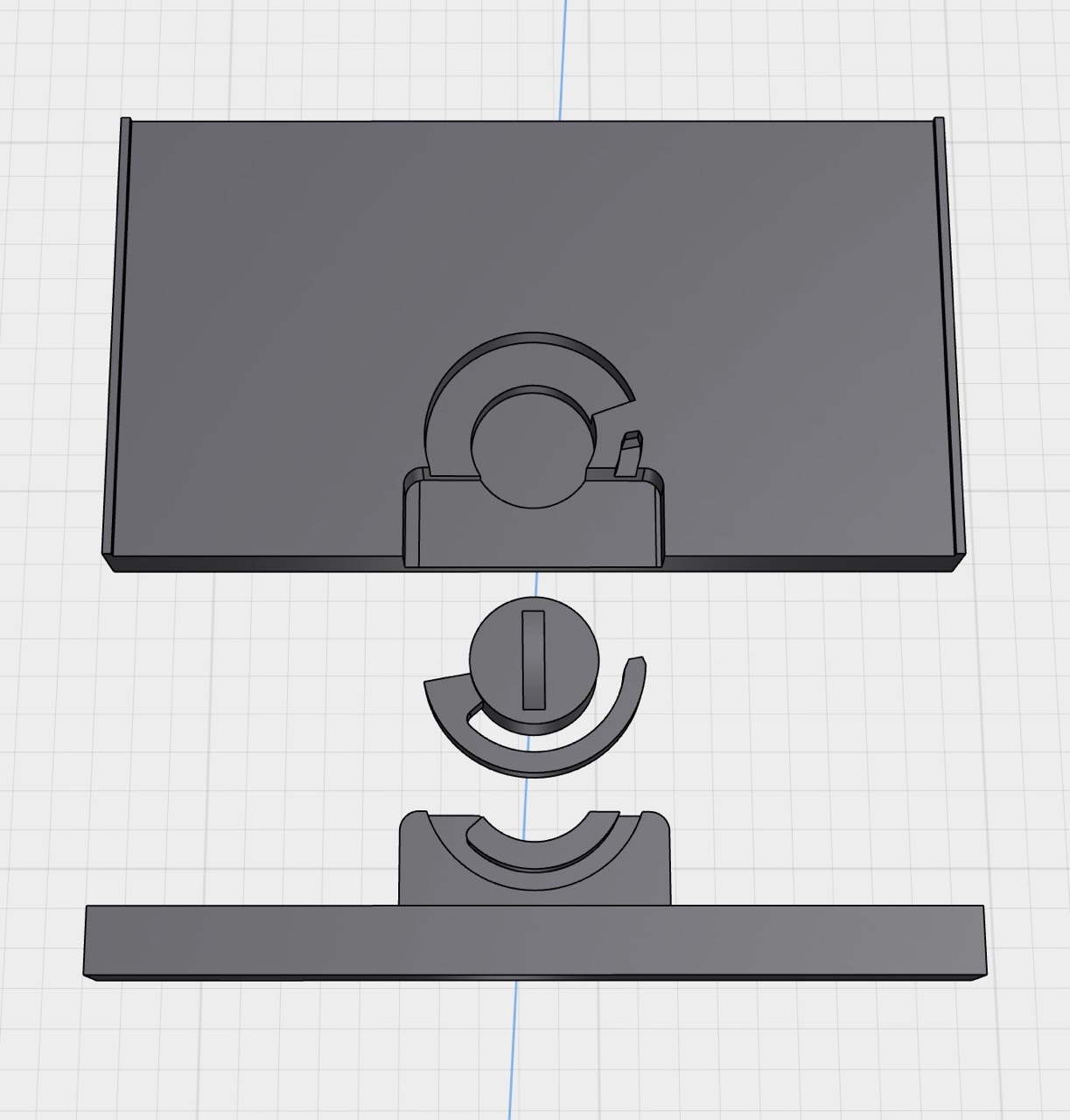

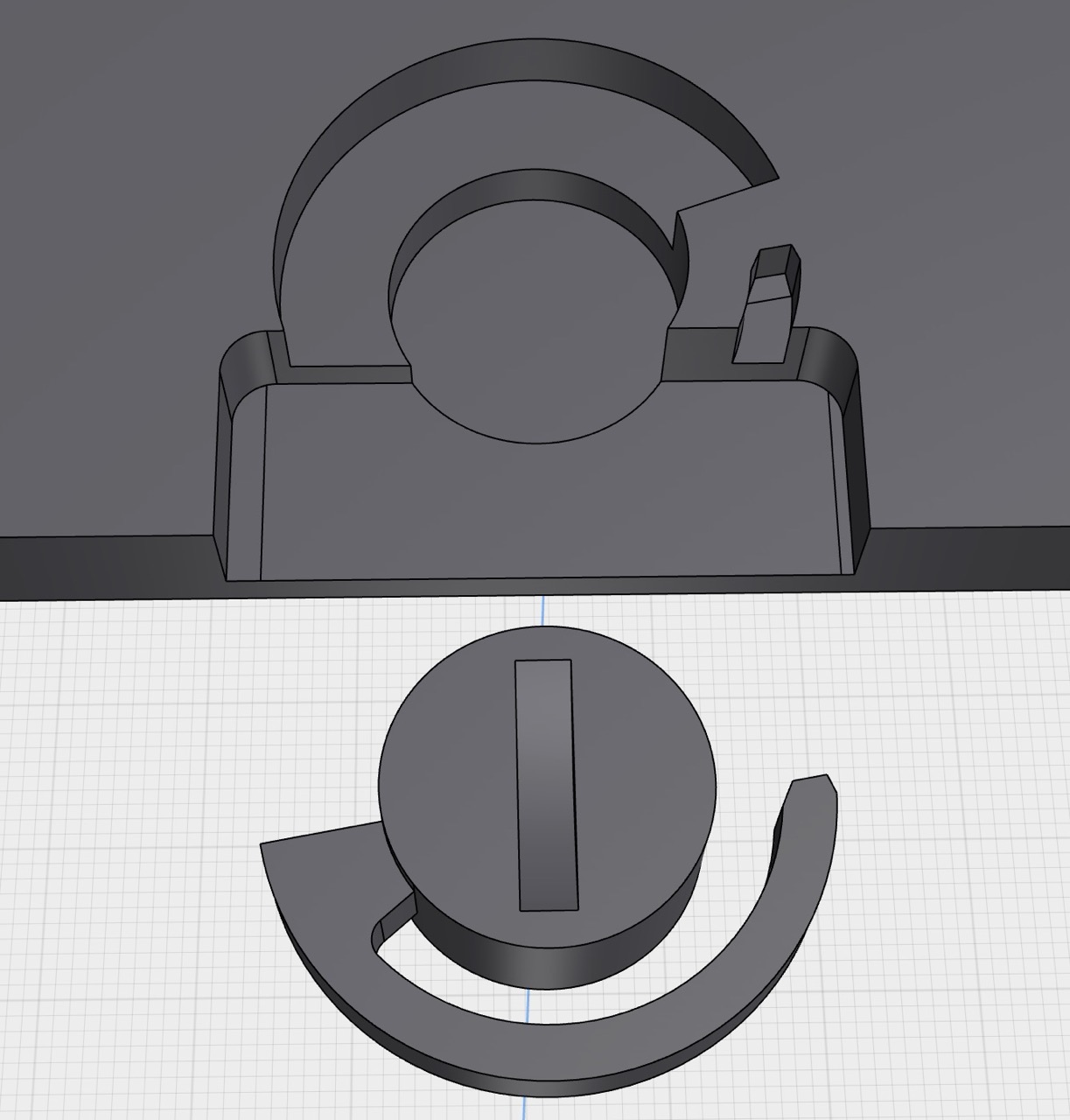

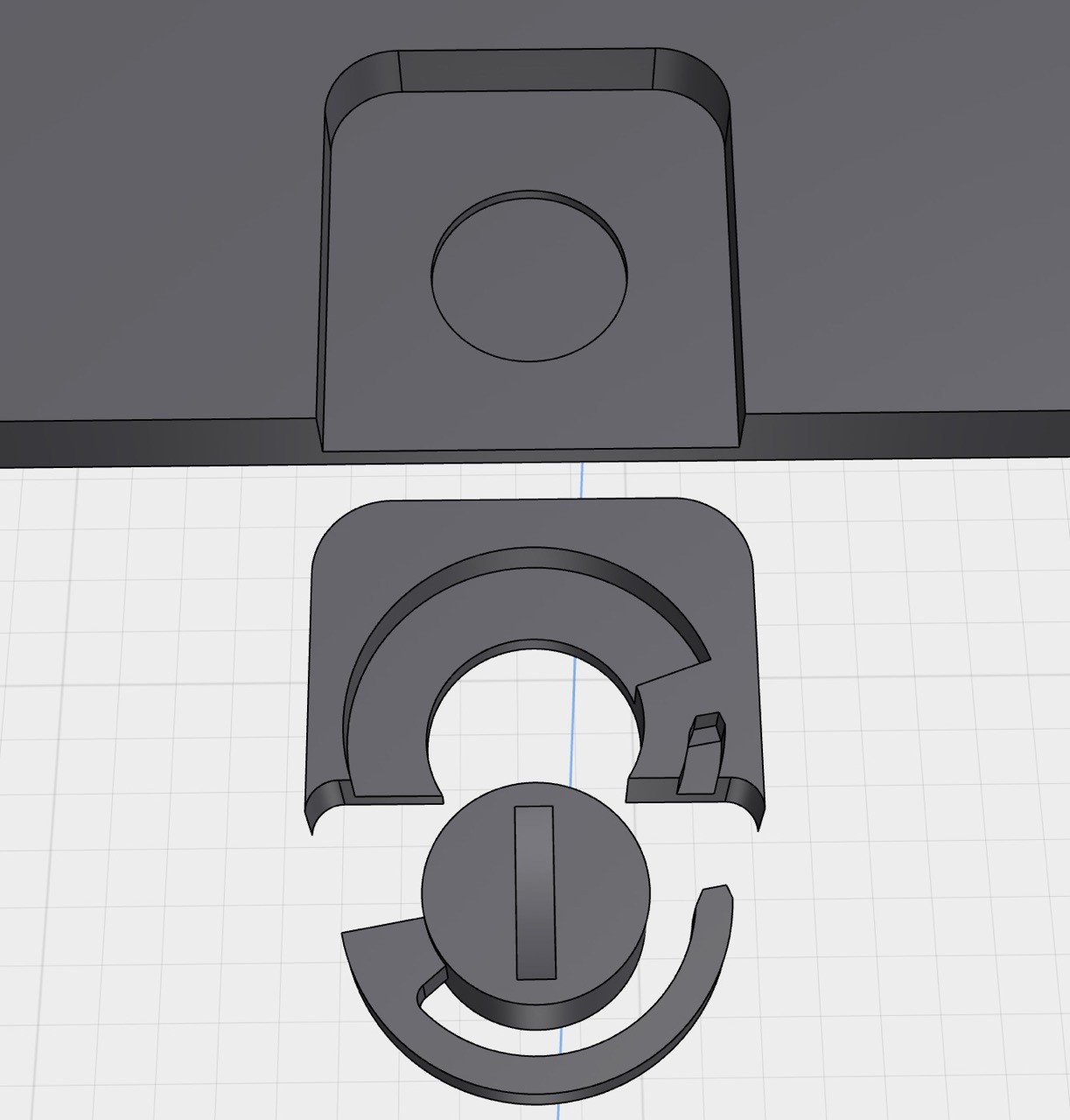

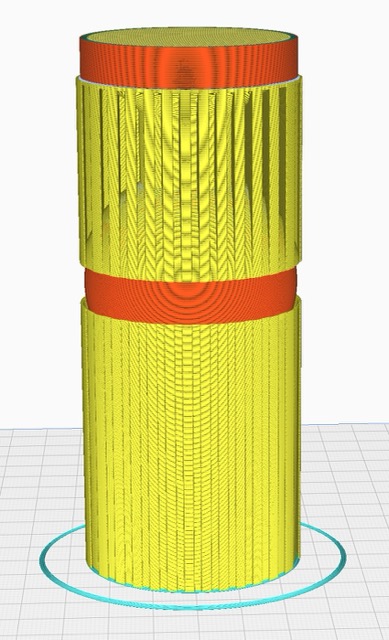

Example model

Uses 82g filament

Uses 49g filament

Uses 43g filament

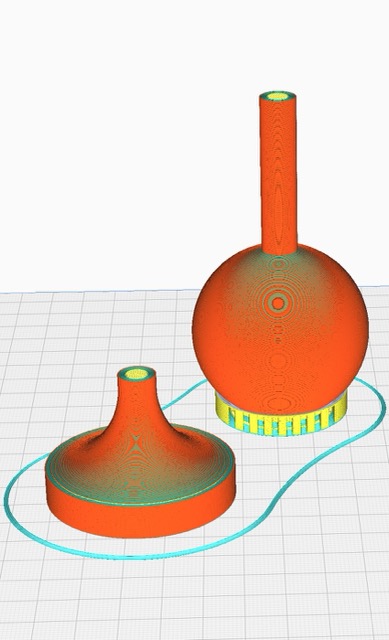

Break down big parts

Are you making a big object with detailed components? Consider separating the big, simple geometries from the small, detailed part and putting them together yourself. Doing this means that we need to throw away less material if the small and detailed part of your object are printed incorrectly.

The example images show a 3D model consisting of a big square geometry with a locking mechanism. The mechanism is significantly more complicated to print and has a higher chance of failure. It is therefore separated as shown so it can be printed by itself and later glued onto the main part.